To understand you must first understand the relation between tightening torque and axial load on the bolt. Perhaps the simplest way to describe it is

T=P*K*D

Where T is the applied torque, P is the load in the bolt, K is what is called a “nut factor”, and D is the bolt diameter. In this equation, it is assumed running torque is equal to zero. Running torque does not add to bolt load. Ever notice how some nuts spin freely on bolts but others take a little effort to turn? The latter case has higher running torque.

In the equation above, K is not a fixed value; it is a function of several things, such as the male to female thread interface, the nut to thread and joint interface, and the head to joint interface. If all surfaces are dry you can get one range of K. Lube just the threads and you will get another. Lube the threads and under the head, you get another. Put Locktite on the threads and you get yet another range. Needless to say, it’s important to understand the physical state (e.g., lubrication) of the joint since for the same torque T, your preload P can be all over the place. In general, as you lube the system, the value of K drops, meaning for the same torque, you get higher preload.

Now in my “real life” as an engineer, I have done torque-tension testing to characterize the range of K for some joints. I collected this data using a calibrated force transducer to measure bolt load and a calibrated torque wrench (I used both a click type and dial type) to apply a specified torque (final torque of 400 lb-in above running torque). My testing was performed with 3/8” NAS bolts, which obviously are much bigger than bolts you find on bicycles, but the fundamental physics holds for smaller bolts. The testing included multiple torque cycles with the bolt in an as-received dry state and also a wet-lubed state. In the aerospace world, we tend to limit the number of times we can re-use a bolt due to uncertainty in the range of K with multiple uses. On bikes, consumers tend to ignore such practices, yet as you will see, doing so can have detrimental effects.

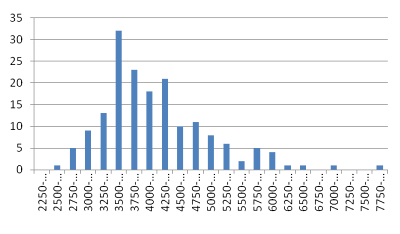

In my first round of testing, from a pool of 10 fasteners I performed 40 torque-tension tests with 4 randomly selected fasteners. After each test I would return the fasteners to the pool and randomly select another 4 for the next test. All bolts were in the unlubed condition. The figure below shows the distribution of bolt load P given the torque T=400 lb-in. The average preload was 4214 lb with a range from 2618 lb to 7760 lb. The 4214 lb average leads to an average nut factor of K=0.253, with a Kmin=0.137 and Kmax=0.407. The distribution plot and the values of Kmin and Kmax clearly show that there is a significant amount of error in preload. With the above values, the preloads are -37.8% and +84.1% from the average preload. That’s some significant error. The high preload values, which are only a couple of samples, could be attributed to something as minimal as body oils contaminating the threads.

I then repeated tests using 6 bolts randomly selected from the pool, and repeated the tests 30 times. During this stage, the preload ranged from 2428 lb to 6482 lb with an average of 3700 lb, leading to K=0.288 and Kmin=0.164 and Kmax=0.439. The min and max preloads were -34.4% to +75.2% from nominal. The important thing here is the increase in average nut factor to 0.288. As more cycles are put on the bolts, wear particles are generated, increasing friction and reducing the efficiency of the bolt/nut. In other words, it now takes more torque to get the desired load.

Next up was a series of 20 tests using 8 randomly selected bolts, but torque was increased to 450 lb-in. The threads were not cleaned, so wear was really an issue. The preload ranged from 2542 lb to 5551 lb with an average of 4040 lb, leading to K=0.297 and Kmin=0.216 and Kmax=0.472. The min and max preloads were -37% to +37.6% from nominal.

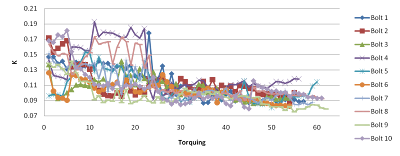

Clearly the number of cycles on the bolt affected the nut factor. Below is a plot of nut factor as a function of torque cycle for each bolt. Two things to take out of this plot are that 1) nut factor increases, and thus bolt preload decreases, with use and 2) for unlubricated bolts the individual K value for a bolt varied widely from one bolt to the next. From a box of 10 bolts, I could randomly select a bolt with a nut factor around K=0.4 while the one next to it may be K=0.2. So, depending on which bolt was picked (and you have no idea of knowing), bolt load could be double or half of desired value.

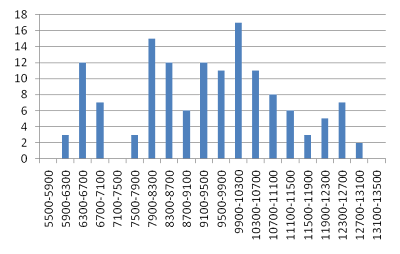

Now when you lubricate bolts, things get quite different. In the first round of testing, I wasn’t completely sure how much lube to apply, so I put just a light coating of wet lube on the threads. I then performed 35 tests with 4 randomly selected bolts from the lot of 10 bolts. The final bolt load distribution had a fairly normal distribution, which was certainly odd, as shown below. This series of tests produced preloads from 5529 lb to 12415 lb with an average of 8988 lb, leading to K=0.119, Kmin=0.086, and Kmax=0.193 and the preload ranging from -38.5% to +38.1% of nominal.

Based on the distribution plot and the wide scatter, I determined I had not apply enough wet lube to the bolt. Adding more lube and performing 30 tests with 6 randomly selected bolts led to the distribution curve below. This series of tests produced preloads from 7901 lb to 13427 lb with an average of 10693 lb, leading to K=0.1, Kmin=0.079, and Kmax=0.135 and the preload ranging from -26.1% to +25.6% of nominal.

Finally I performed another 20 tests with 8 randomly selected bolts, but I reduced the preload to 300 lb-in, in fear of damaging the force transducers. This series of tests produced preloads from 6751 lb to 10620 lb with an average of 8477 lb, leading to K=0.095, Kmin=0.075, and Kmax=0.119 and the preload ranging from -20.4% to +25.3% of nominal.

The graph below shows the individual values of K for each bolt during each torque cycle. The high nut factors from 1-25 cycles is due to the minimal lube applied. The large drop in K is from a liberal application of wet lube. What this graph shows is that 1) lubricating your bolts reduces the effect of “nut factor creep” due to reducing wear particle generation (which is the function of a lubricant) and 2) less scatter from one bolt to the next (indeed, the range of K is very narrow at around K=0.08 to K=0.12).

So what does all this mumbo jumbo mean for our bicycles? Does all this really matter? Well, yes. As an example, one of my bikes is a Specialized Tarmac Pro. The seat tube collar has a single M5 bolt with a torque callout of 55 lb-in. The stem at the steerer tube interface has 4 M4 bolts with a specified torque of 40 lb-in. That’s all the instruction. Even on Specialized’s website, which provides additional installation instructions for the stem, it merely provides the guidance of tightening in a criss-cross pattern at 5 lb-in increments. No mention is made of how clean the thread interface should be, the cleanliness under the bolt head, or what, if any lubrication should be applied. What about running torque? Both of these interfaces clamp carbon parts, so overload is certainly a concern. Let’s take the seat post collar. With T=55 lb-in and D=5 mm (0.19685 in) and a completely unknown K value, just what the heck kind of load can we expect? The testing above indicates K can be anywhere from K=.137 to K=.472, which leads to a clamp load from 592 lb to 2039 lb assuming the 55 lb-in is the effective torque on the bolt. I have no idea what the crush load of my seat post is, but has Specialized designed it for this range? Or suppose I liberally lube the bolt such that now my nut factor may be as low as K=0.075 as the data I collected suggests. This would cause the clamp load to jump to 3725 lb. This load is disconcerting, as even a NAS fastener with strength of 160 ksi would fail in the threaded section with this load. And I doubt Specialized is providing very high strength fasteners (i.e., greater than 160 ksi) with their builds.

Now let’s look at the several fasteners on a bike and address their function and criticality:

Stem to steerer tube – prevent the stem/bars from rotating relative to the wheel by providing enough resistance through friction (clamp force times friction coefficient). A SLIP CRITICAL interface.

Stem to handlebars – we don’t want those bars slipping while riding, so this is another SLIP CRITICAL interface.

Seat post collar – again, we want to avoid the seat slipping on us, so this is another SLIP CRITICAL interface.

Seat rails – what can we say? Another SLIP CRITICAL interface.

Cranks to bottom bracket – we don’t want the cranks from coming loose, and by providing a lot of tension we can reduce the effect of self-loosening. The higher the preload, the less likely we will experience self-loosening, or the number of cycles to loosen will increase. This is a TENSION CRITICAL interface.

Crank ring bolts – these bolts carry shear, but we don’t want them loosening, so this is also a TENSION CRITICAL interface.

Brakes to frame – another TENSION CRITICAL interface since we don’t want the brakes to fall off.

Front derailleur – well, this depends on whether you have a braze-on or clamp on derailleur. For clamp, it’s SLIP CRITICAL, and for braze-on I’d call it a hybrid of SLIP and TENSION CRITICAL.

Rear derailleur – we don’t want the bolt to loosen on us and cause the derailleur to shift outwards, so I’d call this TENSION CRITICAL.

For the tension critical interfaces, we have to further determine if we truly want high preload to maximize fatigue life or merely have a locking feature to hopefully prevent the bolt from coming out. Honestly, all the interfaces I’d classify as the latter. If the interface is metal-on-metal, I’d just apply lube liberally, preload high by feel, and walk away. If it makes you feel better, throw some locktite on the threads. Do note, however, that locktite cures best in a vacuum, and as we don’t have our own vacuum chambers, we may never get a full cure.

For slip critical interfaces, what I’ve always done, particularly with parts I consider as potentially susceptible to crushing, is to keep the bolt as dry as possible, torque a little, try to move the part, and add additional torque as needed to prevent slipping. My goal is to keep K as high as possible to make the efficiency low, giving me lots of error tolerance. And by creeping up I hit the bear minimum needed for my joint functionality. I wouldn’t use a torque wrench because, as already demonstrated, a torque wrench is COMPLETELY WORTHLESS without knowing the nut factor K for the joint. So with absence of vitally important information, I am forced to use my intuition and feel to make a robust joint. My engineering knowledge guides me to abandon my very field and the governing equations because of the lack of design information on the joint.

There are certainly some esoteric reasons for using a torque wrench on your bike. For one, there’s a liability issue. Should you crash due to a failed interface and sue the bike manufacturer, they could ask if a torque wrench was used (although, honestly, given what I have stated above, the torque call-out is ill-defined at best) and that their client is not liable if said wrench was not implemented. Or if you have a warranty claim against the manufacturer, you could bolster your argument by saying you installed per their recommendations, no matter how dubious those recommendations actually were. Though I must say, even if you did use a torque wrench, unless you have verification (e.g., third party watching over you) you may lose that argument. Or you may just want to play with your new toy.

The data is clear – my testing with aerospace grade fasteners, calibrated torque wrenches, and calibrated load transducers shows min and max preload can vary from -38.5% to +84.1% from nominal. If you think that torque wrench is getting you the correct value, think again. That’s a huge error, and I’ve heard about too many broken carbon bits to put my trust into some number stamped on a part with no other information. Remember, T and K are dance partners. T, the number stamped on the part, needs a little more info to meet up with K and waltz off together.